THERMOPLASTIC COMPOSITE

AR®HT ABRASIVE-RESISTANT THERMOPLASTICS

AR®HT is a proprietary thermoplastic material specifically developed for use as bushings, bearings and wear rings in pumps handling abrasive media up to 250°F (120°C). ARHT provides outstanding chemical, thermal shock and impact resistance, making it a better wear material than traditional rubber, ceramic or bronze materials.

Greene, Tweed’s proprietary AR thermoplastic materials exhibit outstanding wear characteristics in media containing solids. AR combines excellent abrasive resistance, good dry run capability and superior vibration dampening characteristics with no hydrolysis or swell.

ARHT works well in a variety of abrasive pump applications including those working with circulating water, open and closed cooling water, river water, screen wash and crude oil pumps. When using ARHT pump users can operate their equipment with much tighter clearances, boosting efficiency and improving process reliability. ARHT is API 610 approved for stationary wear applications.

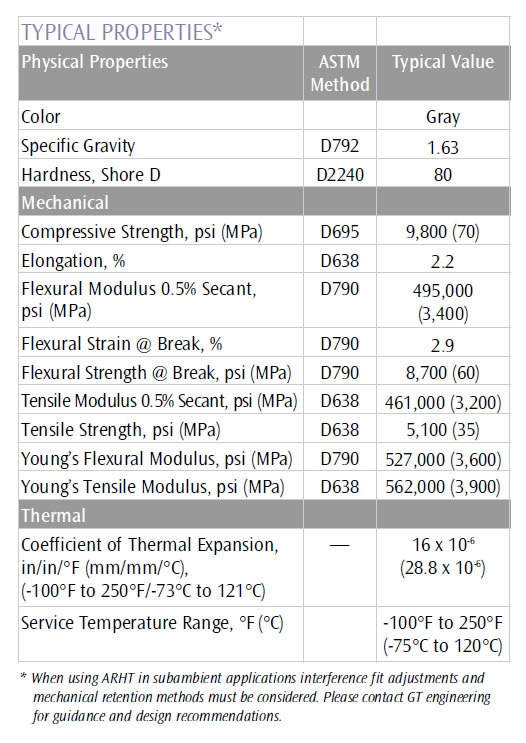

Typical Properties

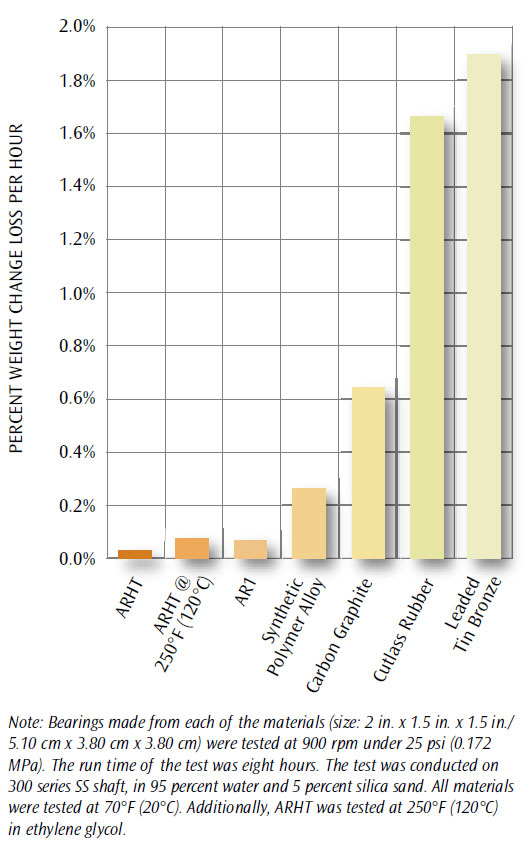

AR® SERIES VS. TRADITIONAL MATERIALS

Features & Benefits, Applications and Availability

FEATURES & BENEFITS

APPLICATIONS

INQUIRE ABOUT THIS PRODUCT