THERMOPLASTIC COMPOSITE

AR®1 ABRASIVE-RESISTANT THERMOPLASTICS

Sand and other abrasives are often a challenge for pump users in the power industry. Clearances on line shaft bearings and bowl wear rings open up, increasing pump vibrations and reducing pump efficiency. Greene, Tweed’s proprietary AR® thermoplastic materials exhibit outstanding wear characteristics in media containing solids.

AR1 offers excellent abrasive resistance as well as chemical resistance approaching that of PTFE. AR1 is rated from ambient to 120°F

(50°C). AR1 is easy to machine, and clearance requirements are easily determined. AR1 works well in a variety of pumps in the power industry including those working with circulating water, open and closed cooling water and river water as well as screen wash pumps. AR materials have performance characteristics that exceed traditional technologies such as cutlass rubber, bronze and carbon materials.

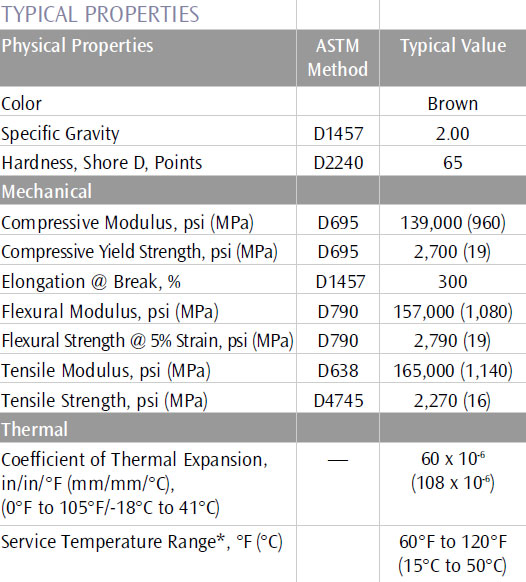

Typical Properties

FEATURES & BENEFITS

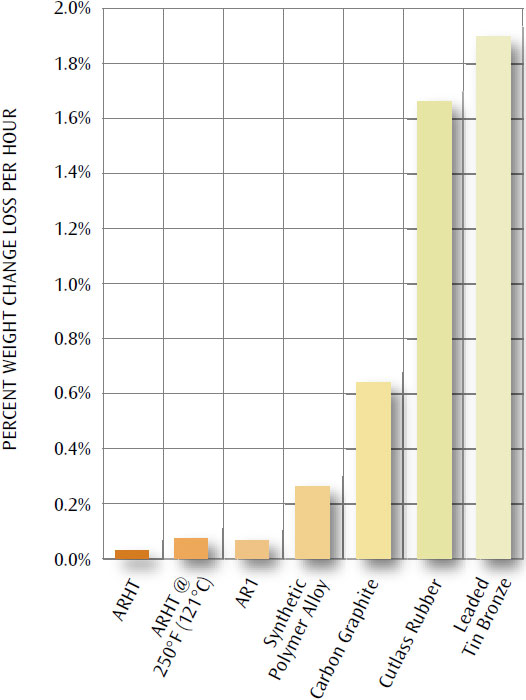

AR® SERIES VS. TRADITIONAL MATERIALS

The chart shows percent weight change (loss) per hour of Greene, Tweed’s ARmaterials compared to traditional materials.

Note: Bearings made from each of the materials (size: 2 in. x 1.5 in. x 1.5 in./ 5.08 cm x 3.81 cm x 3.81 cm) were tested at 900 rpm under 25 psi (0.172 MPa). The run time of the test was eight hours. The test was conducted on 300 series SS shaft, in 95 percent water and 5 percent silica sand. All materials were tested at 70°F (22°C). Additionally, ARHT was tested at 250°F (121°C) in ethylene glycol.

Applications and Availability

APPLICATIONS

AVAILABILITY

INQUIRE ABOUT THIS PRODUCT